01. Technical Strength

Titanium Seller leverages advanced technology and expertise to produce high-performance titanium solutions with precision and durability.

- Reliable Performance

- Cutting-Edge Manufacturing

02. R&D & Innovation

Driven by innovation, we continuously develop new titanium materials and technologies to meet evolving industry demands.

- Advanced Research

- Breakthrough Solutions

03. Delivery Capability

With a streamlined supply chain and efficient logistics, we ensure timely and reliable delivery of premium titanium products.

- Global Reach

- On-Time Delivery

About Us

Precision Titanium Solutions for Critical Industries

Established in 2004, Shaanxi Yuelu Technology Co., Ltd. is a leading supplier of high-performance titanium materials, serving industries such as aerospace, medical devices, and marine engineering. We offer a comprehensive range of titanium plates, sheets, bars, billets, and custom-engineered components, ensuring solutions that meet the highest standards of strength, durability, and precision for complex industry requirements.

more informationPrecision Titanium Processing & Material Supply

Service We Provide

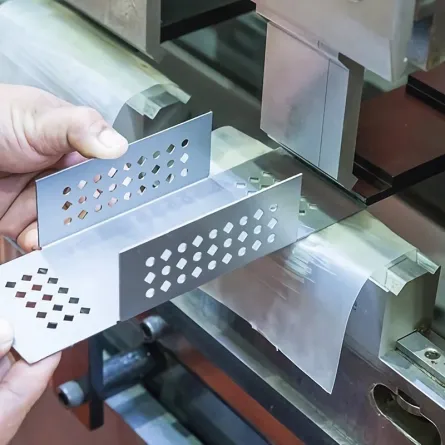

Fabrication

Titanium Fabrication Services At Titanium Seller, we offer high-quality titanium fabrication services tailored to meet the specific needs of your projects. Whether you're in aerospace, automotive, medical, or industrial applications, our expertise in working with titanium ensures that your components are fabricated to the highest standards of quality and precision. From custom machining and welding to bending and forming, our fabrication services cover a broad spectrum of capabilities. We work closely with our clients to deliver the exact specifications they require, ensuring the final product performs reliably under demanding conditions.Our Titanium Fabrication Capabilities 1. Custom Machining We specialize in precision machining of titanium alloys, including turning, milling, drilling, and grinding. Whether you need titanium parts for a small prototype or large-scale production, we provide highly accurate and repeatable results. Our skilled technicians use state-of-the-art machinery to achieve tight tolerances and superior finishes. 2. Titanium Welding Our titanium welding services include TIG welding (Tungsten Inert Gas) and MIG welding (Metal Inert Gas). These methods allow us to join titanium components with precision and strength. We follow strict industry standards to ensure that all welds are free from contamination and provide the highest level of structural integrity. 3. Titanium Forming and Bending Whether you require titanium tubes, plates, or strips to be bent, rolled, or formed into specific shapes, we have the capabilities to handle all types of titanium forming. Our advanced forming techniques ensure that titanium maintains its strength, integrity, and properties throughout the process. 4. Cutting and Shaping We offer custom cutting services for titanium materials, including laser cutting, waterjet cutting, and plasma cutting. Our precision cutting methods allow us to shape titanium components into any size or configuration required, with minimal waste and maximum accuracy. 5. Surface Treatment and Coating We provide surface treatment and coating services to enhance the durability, corrosion resistance, and appearance of titanium parts. Services include anodizing, chemical film coatings, and paint applications, which are especially useful for improving the performance of titanium components in harsh environments.Why Choose Our Titanium Fabrication Services? Precision and Quality We use the latest technology and high-precision equipment to ensure that every fabricated titanium part meets your exact specifications. Our fabrication processes are designed to produce durable and high-quality products, whether you need a single prototype or a large production run. Experience and Expertise With years of experience working with titanium alloys, our team has the knowledge and expertise to handle even the most complex fabrication projects. From aerospace components to medical implants, we understand the unique challenges titanium presents and know how to optimize it for various applications. Custom Solutions We offer custom fabrication solutions tailored to your unique needs. Whether you need specific dimensions, tolerances, or specialized finishes, we can accommodate all requests and provide the best solution for your project. Fast Turnaround Times We understand the importance of timely delivery. Our efficient fabrication processes ensure that we meet deadlines and provide you with the highest quality products on time. Our team works closely with clients to plan and manage projects for timely delivery.Related Services In addition to our fabrication services, we offer a wide range of complementary services to ensure your project is a success: Material Supply We provide a variety of titanium alloys and grades, including Grade 2 (CP Titanium), Grade 5 (Ti-6Al-4V), and custom alloys. We ensure that you receive the right material for your specific application. Cut-to-Length We offer a cut-to-length service for titanium materials, providing you with titanium sheets, plates, or strips in the exact length required for your project. Assembly Services We also provide assembly services, ensuring that your fabricated components are assembled into the final product, ready for installation or use. Prototyping We offer rapid prototyping for titanium components. Whether you need a prototype to test a design or develop a new product, we can provide you with the exact specifications and high-quality materials to bring your project to life.Industries We Serve Our titanium fabrication services are utilized across a variety of industries, including:Aerospace: Custom components, structural parts, and fasteners. Medical: Implants, surgical instruments, and prosthetics. Automotive: High-performance parts and exhaust systems. Industrial: Custom machinery components, valves, and fittings. Marine: Corrosion-resistant components for maritime applications.Conclusion At Titanium Seller, we offer top-tier titanium fabrication services that meet the highest standards of quality, precision, and performance. Whether you need custom machining, titanium welding, bending, or forming, our team is dedicated to delivering results that exceed your expectations. For more information on our fabrication services or to get started on your next project, please Contact Us or Request a Quote today!

Read More

Cut to Length

Precision Cut-to-Length Service for Titanium At Titanium Seller, we offer a Cut-to-Length service that allows you to order titanium materials in the exact length you need. Whether you’re working on small-scale prototypes, engineering projects, or industrial applications, our cutting service ensures you get titanium material cut to your exact specifications, with no waste or excess material. Our Cut-to-Length service is ideal for projects requiring specific lengths of titanium sheet, plate, or strip. We deliver precise, clean cuts that help streamline your production process and minimize material costs.How Our Cut-to-Length Service Works 1. Custom Lengths to Meet Your Specifications We offer custom lengths for titanium sheets, plates, and strips, ensuring that the material you receive is exactly what you need, saving you time and money on unnecessary processing. 2. High Precision Cutting Our state-of-the-art cutting equipment ensures high precision in every cut. Whether you're looking for smooth edges or tight tolerances, we meet your requirements with exceptional accuracy. 3. Fast and Reliable Delivery No matter the size of your order, we guarantee fast and reliable delivery. You can rely on us to provide titanium materials on time, without delays, so your project stays on track. 4. No Minimum Order Requirement There’s no minimum order quantity for our Cut-to-Length service. Whether you need a small batch for a prototype or a larger quantity for mass production, we provide flexible ordering options.Related Services We Offer In addition to Cut-to-Length, we offer several complementary services to ensure your titanium materials meet your specific project requirements: Custom Titanium Fabrication If your project requires more than just length, we also offer custom fabrication services. Our experienced technicians can machine, shape, and form titanium components to your exact design specifications. Titanium Material Supply We provide a wide range of titanium alloys, including Grade 2 (CP Titanium), Grade 5 (Ti-6Al-4V), and other specialty alloys. Choose the right material for your application, and we’ll supply it in the exact quantity you need. Cutting Services for Various Forms Besides sheets, plates, and strips, we also offer cutting services for bars, rods, and tubing. Whatever form your titanium material comes in, we can customize it to your desired length. Fast Shipping Our fast shipping options ensure your material reaches you on time, minimizing project downtime and ensuring that your operations proceed smoothly. We offer global shipping, making our services accessible wherever you are.Why Choose Titanium Seller for Cut-to-Length Services?Precision Cutting: We provide accurate and clean cuts for titanium materials, ensuring that your project is completed with the highest quality. Flexible Ordering: No minimum order quantity. Whether you need a few pieces or bulk, we accommodate your needs. Custom Solutions: Tailored solutions for unique project requirements, including custom shapes, sizes, and materials. Quick Delivery: Get your titanium materials quickly, no matter the size or complexity of your order. Expertise: With years of experience in titanium, we provide expert guidance on material selection and cutting techniques.Conclusion At Titanium Seller, our Cut-to-Length service is designed to meet the needs of customers who require precision cutting and flexible material handling. Whether you’re working with sheets, plates, or strips, we provide custom lengths to fit your exact specifications, ensuring minimal waste and maximum efficiency. We pride ourselves on delivering high-quality titanium materials in the right size for your project. For more information or to get started, Contact Us today, or Request a Quote for your next project.

Read More

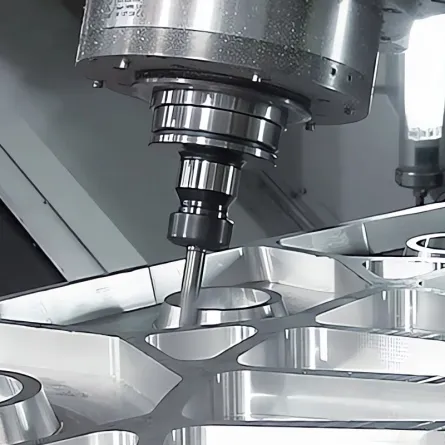

Milling Services

Milling Services for Titanium Alloys Milling is a crucial machining process that involves removing material from a workpiece using rotary cutters. It is widely used in industries requiring high-precision components, and it’s particularly important for processing titanium alloys, which are known for their strength, light weight, and exceptional resistance to corrosion. At Titanium Seller, we provide precision milling services for titanium parts that are used across various industries including aerospace, medical, and automotive sectors. What is Milling? Milling is a machining process that uses rotating cutting tools to remove material from a workpiece. These tools can be moved along multiple axes, allowing for precise control over the shape, size, and surface finish of the part. Milling is typically performed using a vertical milling machine or horizontal milling machine, with the specific type of machine depending on the geometry of the part and the complexity of the machining process. In titanium milling, the material's hardness and heat sensitivity require skilled operators and the right equipment to achieve the desired results without compromising the integrity of the part. Proper milling of titanium alloys allows for the production of components with excellent surface finishes and tight tolerances. Titanium Milling Services We Offer At Titanium Seller, we specialize in high-precision milling of titanium and its alloys. Our milling services are tailored to meet the demanding requirements of industries such as aerospace, medical, defense, and more. We work with various grades of titanium, including Grade 2 (CP Titanium) and Grade 5 (Ti-6Al-4V), and can provide you with customized solutions based on your project specifications. Our Milling Services Include:Titanium Milling (2D and 3D Machining): Whether it's simple 2D shapes or complex 3D geometries, our milling services can produce a wide variety of components. CNC Milling: Using CNC (Computer Numerical Control) machines, we ensure that your titanium parts are milled with exceptional accuracy and repeatability. Custom Titanium Parts: From prototypes to full-scale production, we can mill custom titanium components tailored to your specific needs. Surface Finishing: Our milling process ensures high-quality surface finishes, which can be further enhanced with post-processing such as polishing, anodizing, or coating. Titanium Alloys Milling: We can mill a wide range of titanium alloys, including Grade 5, Grade 23 (Ti-6Al-4V ELI), and others, to meet the most stringent material requirements.Advantages of Milling TitaniumHigh Precision: Achieve tight tolerances and fine details for critical parts. Complex Geometries: Milling allows for the production of both simple and complex geometries, from flat surfaces to intricate shapes. Excellent Surface Finish: Milling can provide smooth surface finishes that reduce the need for additional finishing processes. High Material Removal Rate: Milling is a relatively fast method for removing large volumes of titanium material, making it suitable for large batch productions. Customizable: Our milling services are highly flexible, allowing for the production of both small and large quantities of titanium components.Industries That Benefit from Titanium Milling Titanium's unique properties make it a material of choice in several high-performance industries. Our milling services are ideal for creating parts and components in the following industries:Aerospace: Titanium is extensively used in the aerospace sector for manufacturing components such as turbine blades, airframes, and engine parts due to its strength-to-weight ratio and corrosion resistance. Medical: Titanium's biocompatibility and resistance to corrosion make it ideal for surgical instruments, implants, and prosthetics. Automotive: High-performance vehicles use titanium for parts like exhaust systems and engine components to improve efficiency and reduce weight. Defense & Military: Titanium is used for creating lightweight, durable components for defense applications such as armor plating and weapon systems. Marine: Titanium’s corrosion resistance makes it an ideal material for marine equipment exposed to harsh saltwater environments.Why Choose Us for Titanium Milling? At Titanium Seller, we pride ourselves on our ability to deliver high-quality titanium milling services that meet the strictest industry standards. Here's why we stand out:Expertise in Titanium Alloys: We have years of experience working with titanium, and our experts understand the complexities of machining titanium alloys. Advanced Equipment: Our state-of-the-art CNC milling machines allow us to produce highly precise and consistent results. Custom Solutions: Whether you need small-scale prototypes or large production runs, we offer flexible solutions tailored to your needs. Quality Assurance: We implement strict quality control measures to ensure that every titanium part we mill meets your exact specifications. Fast Turnaround: We provide fast, reliable service with minimal lead times, ensuring you get the components you need on time.Applications of Titanium Milling Our titanium milling services are used to manufacture a wide range of components, including:Aerospace Parts: Turbine blades, engine components, and structural elements. Medical Devices: Implants, surgical instruments, and prosthetics. Automotive Parts: Exhaust systems, engine parts, and custom vehicle components. Marine Equipment: Saltwater-resistant components, hull parts, and fittings. Industrial Equipment: Pumps, valves, and other high-performance parts.Conclusion Titanium milling is a highly specialized process that requires precision, skill, and the right equipment. At Titanium Seller, we have the expertise and technology to provide you with custom titanium parts that meet your specifications. Whether you need a prototype or a large production run, we are committed to delivering quality, precision, and performance. For more information or to discuss your milling project, please Contact Us or Request a Quote today!

Read MoreOur FACILITIES

TITANIUM PLATE & BAR CUTTING FACILITIES

Manual Lathe

Handles titanium and other metals for turning and shaping operations.

Band Saw Cutting

Efficiently cuts titanium and other metals with a high-performance band saw.

Milling Machine

Processes titanium and metal components with precision cutting and shaping.

Polishing Machine

Enhances surface finish for titanium and metal parts.

Sheet Metal Shearing Machine

Guillotine shearing for titanium sheets up to 3mm thick with precision and efficiency.

Water-Jet Cutting Machine

High-precision waterjet cutting for titanium and other metals, ensuring clean, accurate, and efficient processing.