Titanium Sheets & Plates

Titanium Sheets & Plates

An Introduction to Versatile Titanium Sheets & Plates

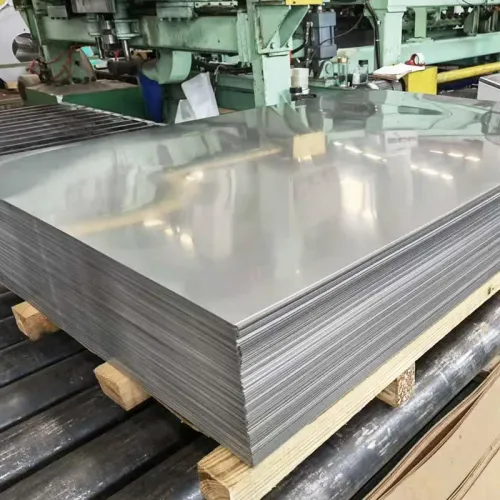

Titanium sheets and plates are the foundational forms of titanium, representing one of the most versatile and widely used product types in the industry. Produced by hot and cold rolling slabs into flat products, they are differentiated by thickness: “sheet” typically refers to material under 6.0 mm thick, while “plate” refers to material 6.0 mm and thicker.

These products serve as the starting point for countless fabrication projects, offering an unparalleled combination of high strength-to-weight ratio, exceptional corrosion immunity, and excellent durability. Whether being laser-cut for intricate parts, formed into pressure vessels, or welded into large-scale structures, titanium sheets and plates provide the raw material for innovation in the world’s most demanding engineering fields.

Available Dimensions & Specifications

We stock a comprehensive inventory of titanium sheets and plates to meet a wide range of industrial and commercial needs.

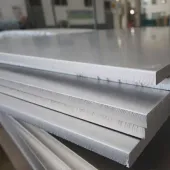

- Thickness:

- Sheet: 0.5 mm to 5.99 mm (0.020” to 0.236”)

- Plate: 6.0 mm to 100 mm (0.236” to 4.0”)

- Standard Sizes:

- 1000mm x 2000mm

- 1220mm x 2440mm (4 ft x 8 ft)

- 1500mm x 3000mm

- Surface Finish: Standard Mill Finish (No. 1 / HRAP), Pickled, or Sandblasted.

- Standards: Primarily manufactured to ASTM B265 specifications.

- Services: Custom laser, waterjet, or plasma cutting available to your specifications.

Common Titanium Sheet & Plate Grades

The selection of a specific grade is determined by the application’s requirements for strength, formability, and corrosion resistance.

| Grade | Common Name(s) | Key Characteristics & Features | Typical Sheet & Plate Applications |

|---|---|---|---|

| Grade 2 | CP Ti Grade 2 | The most widely used grade. Offers excellent balance of moderate strength, good formability, and outstanding corrosion resistance. | Chemical processing tanks, pressure vessels, heat exchanger plates, architectural cladding, piping systems. |

| Grade 5 | Ti-6Al-4V | The “workhorse” titanium alloy. Very high strength, good fatigue resistance. More difficult to form than CP grades. | Aerospace structural components (wings, fuselage), armor plating, high-performance motorsport chassis parts. |

| Grade 1 | CP Ti Grade 1 | The softest and most ductile grade. Provides the best formability for complex or deep-drawing applications. | Plate-and-frame heat exchangers, expanded metal anodes, applications requiring extreme forming. |

| Grade 7 | Ti-0.2Pd | Mechanically identical to Grade 2, but with palladium added for enhanced corrosion resistance, especially against crevice corrosion. | Linings for highly corrosive chemical vessels, specialized desalination equipment, and process piping. |

| Grade 12 | Ti-0.3Mo-0.8Ni | ”Near-alpha” alloy with enhanced high-temperature strength and superior crevice corrosion resistance compared to CP grades. | Heat exchangers in higher temperature/mildly reducing environments, chemical processing equipment. |

Example Applications of Titanium Sheets & Plates

The robust and reliable nature of titanium plates and sheets makes them a cornerstone material across numerous industries.

Aerospace & Defense

- Airframe Structures: Used for fuselage skins, wing structures, bulkheads, and engine nacelles where weight reduction and strength are paramount.

- Armor Plating: Titanium plate offers excellent ballistic protection at a lower weight than steel, used in military vehicles and personal protection.

- Engine Components: Formed and fabricated into parts for jet engines that must withstand high temperatures and stress.

Chemical Processing & Energy

- Pressure Vessels & Tanks: The superior corrosion resistance makes titanium ideal for storing and processing aggressive chemicals, acids, and chlorides.

- Plate Heat Exchangers: Thin titanium sheets are corrugated and stacked to create highly efficient and corrosion-proof heat transfer units.

- Desalination Plants: Extensively used for piping, vessels, and heat exchangers that are in constant contact with saltwater.

Marine & Offshore

- Shipbuilding: Used for hull plates on high-speed naval vessels, submarine components, and offshore platform risers and piping.

- Ballast Water Systems: Provides a long-term, maintenance-free solution for piping and valves exposed to corrosive seawater.

Architecture & Construction

- Façades and Roofing: Creates iconic, long-lasting building exteriors that are lightweight and impervious to pollution and acid rain (e.g., Guggenheim Museum Bilbao).

- Sculptures and Monuments: Chosen by artists for its durability, unique luster, and ability to be anodized into different colors.

Quick Contact

Related Products

-

The Building Blocks of Engineering: Key Applications for Titanium Sheets and Plates

Titanium Sheets & Plates

-

Fabricating with Titanium Sheets and Plates: Cutting, Forming, and Welding

Titanium Sheets & Plates

-

Titanium Sheet vs. Plate: A Technical Guide to Selection

Titanium Sheets & Plates