Why Titanium Foil is a Critical Material: Top Industry Applications

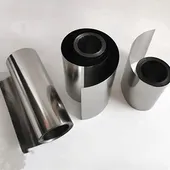

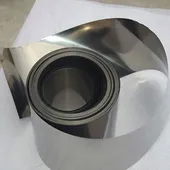

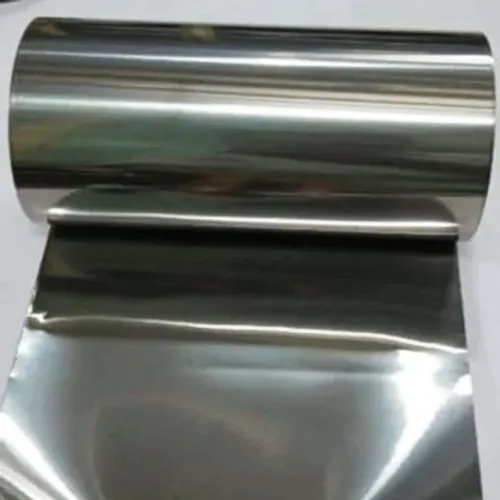

While titanium is renowned for its strength and light weight in bulky applications like aircraft frames, its thinner form—titanium foil—is an unsung hero in countless high-tech fields. Its unique combination of properties makes it an indispensable material where performance cannot be compromised.

Let’s explore the diverse and critical applications where titanium foil excels.

1. Aerospace and Aviation: The Ultimate Weight-Saver

In an industry where every gram counts, titanium foil is a star player. Its exceptional strength-to-weight ratio and high-temperature resistance make it ideal for:

- Heat Shields: Protecting sensitive components from the intense heat of engines and re-entry.

- Honeycomb Panels: Used as a core material for lightweight yet rigid structural panels in wings and fuselages.

- Acoustic Insulation: Thin foils are used in engine nacelles to dampen noise, improving passenger comfort and meeting strict regulations.

2. Medical and Healthcare: The Biocompatible Choice

Titanium is famously biocompatible, meaning it is non-toxic and not rejected by the human body. This makes titanium foil essential for:

- Pacemaker and Defibrillator Casings: The foil forms a hermetically sealed, corrosion-proof case that protects the device’s sensitive electronics from the body’s internal environment.

- Surgical Instruments: Its light weight reduces surgeon fatigue, and it can be repeatedly sterilized without degradation.

- Implants and Dental Applications: Used in components for cranial meshes and other delicate implants where a thin, strong, and biocompatible material is required.

3. Chemical Processing Industry: The Corrosion Fighter

The chemical industry deals with some of the most corrosive substances known. Titanium foil provides a robust barrier against chemical attack.

- Vessel and Tank Linings: Applying a thin layer of titanium foil inside a steel vessel provides superior corrosion resistance at a fraction of the cost of a solid titanium vessel.

- Heat Exchangers: In plate-and-frame heat exchangers, thin, corrugated titanium foils allow for efficient heat transfer between aggressive fluids without succumbing to corrosion.

4. Electronics and Audio: Precision and Performance

The world of high-end electronics and audio demands materials that are light, stiff, and non-magnetic.

- Speaker Diaphragms: Titanium foil is used in high-frequency tweeters and headphone drivers. Its stiffness and low mass allow it to vibrate rapidly and accurately, reproducing sound with exceptional clarity and detail.

- Electronics Casings: For premium devices, titanium foil can be used to create durable, lightweight, and aesthetically pleasing enclosures.

- Capacitors: In specialized high-voltage capacitors, titanium foil can be used as an electrode material due to its stable oxide layer.

Quick Contact

Related Products

Product Categories

- Titanium Anode Basket 1

- Titanium Foils 1

- Titanium Pipes 1

- Titanium Rods 1

- Titanium Tubes 1

- Titanium Wires 3

- Nuts & Bolts 1

- Special Titanium Alloys 1

- Titanium Anodes & Electrodes 1

- Titanium Equipment 1

- Titanium Mesh 1

- Titanium Sheets & Plates 1

- Titanium rods 3

- Titanium foils 3

- Titanium sheets and plates 3

- Titanium pipes 3