Not All Baskets Are Equal: A Guide to Selecting the Right Titanium Anode Basket

Choosing the right titanium anode basket is crucial for optimizing your electroplating line. A well-designed basket ensures efficient current flow and trouble-free operation, while a poor choice can lead to plating defects and maintenance headaches. This guide covers the key design features to consider when making your selection.

1. Basket Shape and Size: Conforming to Your Tank

The first consideration is geometry. The basket should fit your tank and complement the parts you are plating.

- Rectangular Baskets: The most common type, ideal for plating flat panels or parts racked in a planar configuration. The length and width should be chosen to provide uniform current distribution across the cathode.

- Round/Cylindrical Baskets: Perfect for barrel plating or for plating the inside of cylindrical parts. They provide a more uniform current field in these specific applications.

- Size Matters: The basket should be large enough to hold an adequate supply of anode material, reducing the frequency of refilling. However, it shouldn’t be so large that it impedes solution flow or gets too close to the parts being plated (which can cause burning/high current density spots).

2. Mesh Specifications: Balancing Flow and Containment

The titanium mesh is the heart of the basket. The choice of mesh opening is a trade-off:

- Standard Mesh: Offers excellent solution flow and rinsing, which is critical for consistent plating. It works perfectly with standard anode nuggets or spheres.

- Fine Mesh (Micromesh): Required if you are using very small or irregularly shaped anode pieces that could fall through standard mesh. The trade-off is slightly reduced solution flow, which can be a factor in some high-agitation baths.

3. Hook Design: The Critical Connection

The hook does two things: supports the weight of the basket and delivers the electrical current.

- Current-Carrying Capacity: The hook’s cross-sectional area must be sufficient to carry the required amperage without overheating. Undersized hooks are a common point of failure.

- Hook Style: The shape (e.g., knife-edge, round) should provide a solid, stable connection with your anode busbar to ensure uninterrupted current flow. Double contact hooks are often used for heavier baskets to provide better stability and current distribution.

- Solid Construction: Hooks should always be made of solid titanium and securely welded to the basket frame for maximum strength and conductivity.

4. Anode Bags: The Essential Accessory

Though not part of the basket itself, an anode bag is almost always used with it. This fabric bag (made of materials like polypropylene) fits snugly over the basket. Its purpose is to trap any small anode fines or insoluble particles that break off, preventing them from floating into the solution and causing roughness on the plated parts. Always choose a bag made from a material compatible with your plating chemistry.

Conclusion: A Thoughtful Choice

Selecting a titanium anode basket isn’t just about buying a container. It’s about investing in a piece of engineered equipment. By carefully considering the shape, mesh, and hook design, you can ensure you get a basket that is perfectly suited to your process, leading to better plating quality and a more efficient operation.

Quick Contact

Related Products

-

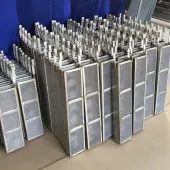

Introduction to Titanium Anode Baskets

Titanium Anode Basket

-

Titanium anode basket care a guide to longevity performance

Titanium Anode Basket

-

The Workhorse of Modern Electroplating: Understanding the Titanium Anode Basket

Titanium Anode Basket