The Workhorse of Modern Electroplating: Understanding the Titanium Anode Basket

The Workhorse of Modern Electroplating: Understanding the Titanium Anode Basket

In the electroplating industry, consistency is king. Achieving a uniform, high-quality finish depends on maintaining a stable process, and the anode is a critical part of that equation. For decades, the solution has been the titanium anode basket, a simple yet revolutionary device that has become an indispensable workhorse in plating shops worldwide.

So, what exactly is a titanium anode basket, and why is it superior to traditional solid anodes?

What is a Titanium Anode Basket?

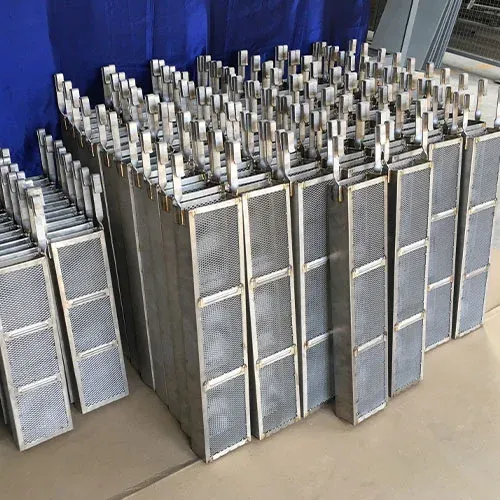

A titanium anode basket is a specially constructed container made from high-purity, corrosion-resistant titanium. It typically consists of a titanium mesh body and a solid titanium hook. Its purpose is not to be the anode itself, but to hold smaller, soluble anode materials (like nickel spheres, copper nuggets, or zinc balls) within the plating bath.

The titanium basket is submerged in the electrolyte and hung from the anode busbar via its hook. The electrical current flows through the titanium basket to the soluble anode material inside, which then dissolves evenly into the plating solution to replenish the metal ions being plated onto the parts.

The Key Advantages Over Traditional Anodes

The shift from solid slab anodes to titanium anode baskets was driven by several powerful benefits:

-

Constant Anode Surface Area: As a solid anode dissolves, its surface area shrinks, causing current density to fluctuate and leading to inconsistent plating thickness. A titanium anode basket, when kept properly filled, maintains a near-constant surface area, ensuring stable current distribution and uniform plating results.

-

Cost Savings & Material Efficiency: Soluble anode materials like spheres and nuggets are generally less expensive than forged or rolled solid anodes. Baskets allow you to use these more economical forms and consume nearly 100% of the material, eliminating the waste associated with “stub ends” of solid anodes.

-

Reduced Downtime and Labor: Instead of halting production to replace an entire slab anode, operators can simply top up the basket with new material as needed. This significantly reduces maintenance time and labor costs.

-

Superior Durability: Titanium is virtually immune to corrosion in most plating solutions (e.g., nickel, copper, zinc). The basket itself does not dissolve, providing decades of reliable service. The titanium forms a stable, conductive passive oxide film that allows current to pass through without the basket itself being consumed.

A Cornerstone of Quality Plating

By providing stability, efficiency, and cost-effectiveness, the titanium anode basket has fundamentally improved the electroplating process. It allows for tighter process control, higher quality finishes, and a more economical operation. For any modern plating line, it’s not just an accessory; it’s an essential component for success.

Quick Contact

Related Products

-

Not All Baskets Are Equal: A Guide to Selecting the Right Titanium Anode Basket

Titanium Anode Basket

-

Titanium anode basket care a guide to longevity performance

Titanium Anode Basket

-

Introduction to Titanium Anode Baskets

Titanium Anode Basket