Choosing the Right MMO Coating for Your Titanium Anode: A Technical Guide

While all Mixed Metal Oxide (MMO) titanium anodes are built on a stable titanium substrate, their performance is dictated by one critical element: the catalytic coating. The specific blend of precious metal oxides in the coating is engineered for a specific electrochemical reaction. Choosing the wrong coating can lead to inefficiency, damage to the anode, and poor results.

This guide will help you understand the two primary types of MMO coatings to ensure you select the perfect anode for your process.

The Two Primary Reactions: Chlorine vs. Oxygen Evolution

In most industrial electrolysis, the primary anodic reaction is either the evolution of chlorine gas or oxygen gas. Each reaction requires a different catalyst for optimal performance.

1. Ruthenium-Based Anodes (for Chlorine Evolution)

These anodes use a coating primarily based on a Ruthenium-Iridium alloy (Ru-Ir).

- How It Works: This coating has a very low overpotential for the chlorine evolution reaction (CER). This means it requires significantly less energy to produce chlorine gas from a chloride-rich solution (like brine or seawater).

- Key Characteristic: Highly efficient for chlorine production but can be damaged if forced to operate in an oxygen-evolving environment, such as a low-chloride or sulfate electrolyte.

- Primary Applications:

- Chlor-Alkali Industry: The cornerstone of chlorine and caustic soda production.

- Sodium Hypochlorite Generation: For disinfecting water in swimming pools, water treatment plants, and ballast water systems.

- Cathodic Protection in Seawater: Where the electrolyte is naturally high in chlorides.

2. Iridium-Based Anodes (for Oxygen Evolution)

These anodes typically use a coating of Iridium-Tantalum oxides (Ir-Ta).

- How It Works: This formulation is specifically designed to be stable and efficient during the oxygen evolution reaction (OER). It resists passivation (the formation of a non-conductive layer) that would quickly destroy a ruthenium-based anode under these conditions.

- Key Characteristic: Extremely durable in low-chloride, sulfate, or other oxygen-rich environments. It is the go-to choice when oxygen evolution is the dominant or desired reaction.

- Primary Applications:

- Electrowinning of Metals: Extracting copper, zinc, nickel, and cobalt from sulfate-based solutions.

- Electroplating: Used in various plating processes, especially those involving additives that promote oxygen evolution.

- Water Treatment: In advanced oxidation processes or when dealing with freshwater.

- Cathodic Protection in Soil, Freshwater, or Concrete: Where the electrolyte has low or negligible chloride content.

Beyond the Coating: Other Factors

While the coating is paramount, also consider:

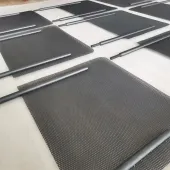

- Substrate Form: Anodes can be made as plates, meshes, tubes, rods, or ribbons to suit the geometry of your cell or application. Mesh is often preferred for better electrolyte flow and gas release.

- Current Density: Your operational current density (Amps/m²) will influence the required coating thickness and expected lifespan.

Making the Right Choice

The rule is simple: match the anode to the reaction.

- For Chloride-rich environments -> Choose Ruthenium-based (Ru-Ir) coatings.

- For Sulfate or low-chloride environments -> Choose Iridium-based (Ir-Ta) coatings.

Consulting with our material experts will ensure you receive a titanium anode perfectly tailored to your process, maximizing efficiency and guaranteeing a long service life.

Quick Contact

Related Products

-

Titanium Anodes & Electrodes

Titanium Anodes & Electrodes

-

The Unsung Guardian: How Titanium Anodes Revolutionize Cathodic Protection

Titanium Anodes & Electrodes

-

Elevate Your Industrial Efficiency with Premium Titanium Anodes

Titanium Anodes & Electrodes