Titanium Anodes & Electrodes

An Introduction to Dimensionally Stable Anodes (DSA)

Titanium anodes, more accurately known as Dimensionally Stable Anodes (DSA) or Mixed Metal Oxide (MMO) anodes, are highly specialized electrodes used in a wide range of electrochemical processes. They consist of a titanium substrate (in the form of a plate, mesh, tube, or rod) which is coated with a thin, catalytically active layer of mixed metal oxides.

The titanium substrate provides excellent corrosion resistance, mechanical stability, and electrical conductivity, acting as a durable backbone. The oxide coating, however, is the true workhorse. It is specifically engineered to facilitate a desired electrochemical reaction (like chlorine or oxygen evolution) efficiently and with a low consumption rate. This combination results in an electrode with an exceptionally long service life and stable performance, making it a cornerstone of modern electrochemistry.

Common Anode Coatings and Their Functions

The type of mixed metal oxide (MMO) coating determines the anode’s primary function and suitability for a specific application. Each coating is optimized to catalyze a particular reaction.

| Coating Type | Primary Reaction | Key Characteristics & Features | Typical Applications |

|---|---|---|---|

| Iridium-Tantalum (Ir-Ta) Oxide | Oxygen Evolution | Highly efficient for oxygen evolution in acidic or neutral solutions. Very robust and long-lasting. | Electrowinning of metals (Copper, Zinc, Nickel), electroplating, cathodic protection, water treatment (electro-oxidation). |

| Ruthenium-Iridium (Ru-Ir) Oxide | Chlorine Evolution | Specifically designed for high efficiency in chlorine evolution from chloride-containing solutions (brine/seawater). | Chlor-alkali industry, seawater electrochlorination (for biofouling prevention), swimming pool chlorinators. |

| Platinum (Pt) Coated/Plated | Oxygen/Chlorine Evolution | A highly versatile but more expensive option. Excellent catalytic activity and stability in various electrolytes. | High-purity water electrolysis, precious metal plating (gold, rhodium), cathodic protection in demanding environments. |

| Lead Dioxide (PbO₂) Coated | High Oxygen Overpotential | Extremely high oxygen evolution potential, making it ideal for powerful oxidation processes where other anodes might fail. | Wastewater treatment (degradation of organic pollutants), perchlorate production, hydrometallurgy. |

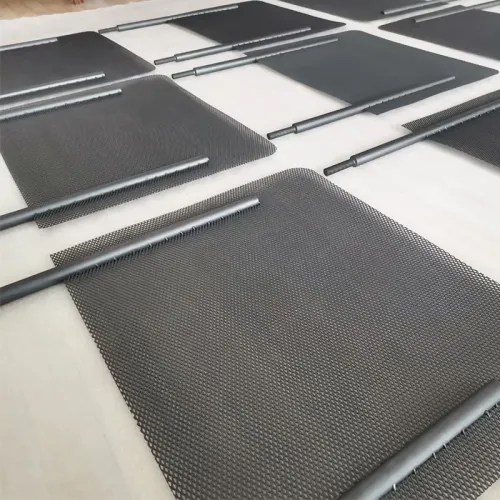

Available Forms and Geometries

We manufacture titanium anodes in various shapes and sizes, custom-fabricated to fit your specific electrochemical cell or reactor.

- Plates: Solid sheets for plate-and-frame cells and electrowinning.

- Mesh: Expanded or woven mesh provides a high surface area-to-volume ratio, ideal for efficient current distribution. This is the most common form.

- Tubes: Tubular anodes are used inside larger pipes or for cylindrical cell designs.

- Rods & Wires: Used for smaller-scale applications, laboratory setups, or for cathodic protection of internal surfaces.

- Custom Assemblies: We can design and build complex anode structures, including baskets, concentric rings, and other custom geometries.

Example Applications of Titanium Anodes

Titanium anodes are critical components in a vast array of industrial processes.

Water Treatment & Disinfection

- Electrochlorination: On-site generation of sodium hypochlorite from seawater or brine to disinfect drinking water, cooling water circuits, and swimming pools.

- Wastewater Treatment: Advanced Oxidation Processes (AOPs) use titanium anodes to break down stubborn organic pollutants (dyes, phenols, pharmaceuticals) in industrial wastewater.

Hydrometallurgy & Metal Recovery

- Electrowinning: Used to recover non-ferrous metals like copper, nickel, zinc, and cobalt from leach solutions by plating them onto cathodes.

- Metal Recycling: Electro-refining processes to purify metals or recover valuable metals from plating rinse waters.

Cathodic Protection (ICCP)

- Marine Structures: Protecting ship hulls, offshore platforms, and pipelines from corrosion using an Impressed Current Cathodic Protection (ICCP) system where the MMO anode is the key component.

- Concrete Structures: Preventing corrosion of steel rebar in bridges, buildings, and parking garages.

Electroplating

- Functional & Decorative Plating: Used as inert anodes in chrome, nickel, and precious metal plating baths to provide the necessary current without contaminating the plating solution.

Chlor-Alkali Industry

- Chlorine Production: The foundational technology for the industrial production of chlorine gas and sodium hydroxide (caustic soda) from brine electrolysis.

Quick Contact

Related Products

-

Choosing the Right MMO Coating for Your Titanium Anode: A Technical Guide

Titanium Anodes & Electrodes

-

Elevate Your Industrial Efficiency with Premium Titanium Anodes

Titanium Anodes & Electrodes

-

The Unsung Guardian: How Titanium Anodes Revolutionize Cathodic Protection

Titanium Anodes & Electrodes