The Unsung Guardian: How Titanium Anodes Revolutionize Cathodic Protection

Corrosion costs the global economy trillions of dollars each year, silently degrading critical infrastructure like pipelines, bridges, ships, and storage tanks. One of the most powerful tools in the fight against this decay is Impressed Current Cathodic Protection (ICCP), a technology where the MMO titanium anode has become the undisputed champion.

Let’s explore how these remarkable components act as unsung guardians, preserving our most valuable assets.

What is Impressed Current Cathodic Protection (ICCP)?

All metals have a natural tendency to corrode when placed in an electrolyte (like soil, seawater, or concrete). ICCP works by overpowering this natural corrosive action. A system consists of:

- A DC Power Source (Rectifier).

- An Anode (the MMO titanium anode) that discharges current.

- The Structure to be Protected (the Cathode).

- The Electrolyte (soil, water, etc.) that completes the circuit.

The rectifier pushes a small electrical current from the anode, through the electrolyte, and onto the surface of the structure. This makes the entire structure a cathode, effectively halting the corrosion process.

Why MMO Titanium Anodes are the Gold Standard for ICCP

Previously, materials like graphite or high-silicon cast iron were used for ICCP anodes. However, they were heavy, brittle, and consumed themselves over time. MMO titanium anodes solved all these problems, offering a suite of unparalleled advantages:

-

Dimensional Stability & Long Life: Unlike consumable anodes, titanium anodes do not degrade. They maintain their shape and size for decades, providing stable, predictable protection with minimal maintenance. A typical design life is 20-40 years or more.

-

High Efficiency & Low Power Costs: The catalytic MMO coating discharges current with very little resistance, significantly reducing the amount of power required from the rectifier. This leads to lower operational energy costs over the system’s lifetime.

-

Lightweight & Versatile: Titanium is incredibly light compared to older materials, making transportation and installation far easier and safer. More importantly, it can be manufactured into various shapes to suit any application:

- Rods & Tubes: For protecting the inside of water tanks or offshore structures.

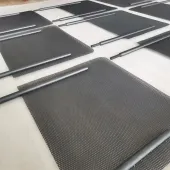

- Ribbons & Meshes: For protecting rebar in concrete bridges and buildings.

- Canister Anodes: Pre-packaged in carbonaceous backfill for easy installation in soil to protect pipelines.

-

Reliability in Harsh Environments: Whether buried in aggressive soil, submerged in corrosive seawater, or embedded in chloride-contaminated concrete, MMO titanium anodes are designed to perform reliably in the world’s toughest conditions.

Preserving the Future with Advanced Materials

From ensuring the integrity of a transcontinental oil pipeline to extending the life of a coastal bridge, MMO titanium anodes are a critical, if often unseen, technology. They represent a smart, sustainable, and highly effective solution for protecting vital infrastructure. By choosing a high-quality MMO titanium anode, you are not just buying a component; you are investing in decades of safety, reliability, and peace of mind.

Quick Contact

Related Products

-

Choosing the Right MMO Coating for Your Titanium Anode: A Technical Guide

Titanium Anodes & Electrodes

-

Elevate Your Industrial Efficiency with Premium Titanium Anodes

Titanium Anodes & Electrodes

-

Titanium Anodes & Electrodes

Titanium Anodes & Electrodes