The Building Blocks of Engineering: Key Applications for Titanium Sheets and Plates

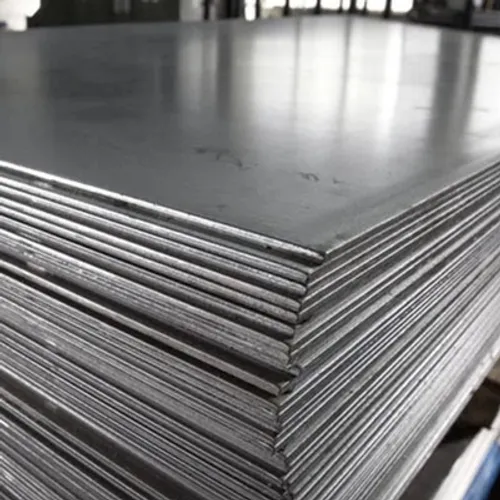

Titanium sheets and plates form the foundation for some of the most demanding engineering projects on Earth and beyond. Their combination of large surface area, structural strength, and outstanding corrosion resistance makes them the ideal material for fabricating robust, long-lasting equipment and structures.

Let’s explore the critical applications built upon titanium sheets and plates.

1. Process Industries: Pressure Vessels and Tanks

This is a primary application for thick titanium plates. In chemical processing, oil & gas, and desalination plants, they are used to construct:

- Pressure Vessels: Titanium’s strength at elevated temperatures and resistance to corrosive chemicals make it perfect for containing high-pressure reactions safely.

- Storage Tanks: For storing highly corrosive materials like acids or chlorides, a tank fabricated from titanium plates offers a service life far exceeding stainless steel.

- Heat Exchanger Shells and Tube Sheets: Thick titanium plates form the structural body and tube-holding plates in large shell-and-tube heat exchangers.

2. Aerospace: Airframe Skins and Structural Components

Both titanium sheets and plates are vital to modern aircraft.

- Fuselage and Wing Skins: Thin titanium sheets are used in areas exposed to high temperatures, such as near the engines, where aluminum would fail.

- Bulkheads and Structural Ribs: Thick titanium plates are machined into the primary structural frames that form the skeleton of an aircraft, providing immense strength and fatigue resistance.

3. Armor and Defense: Superior Ballistic Protection

The high strength and moderate density of titanium plates make them an excellent material for ballistic armor.

- Military Vehicles: Used as appliqué armor on personnel carriers and tanks to protect against projectiles and shrapnel, offering superior protection for its weight compared to steel.

- Personal Protection: Lighter-weight plates are used in high-end body armor vests.

4. Architecture and Design: Aesthetics and Longevity

Titanium sheets offer a unique combination of beauty and permanence for landmark buildings.

- Cladding and Roofing: Famous examples like the Guggenheim Museum in Bilbao use titanium sheets for their exterior. They provide a unique luster and are completely immune to acid rain and urban pollution, ensuring the building looks pristine for centuries.

5. Marine and Offshore: Conquering the Saltwater Environment

Titanium sheets and plates are the ultimate material for marine applications due to their total immunity to saltwater corrosion.

- Shipbuilding: Used for hulls of high-performance submarines, deep-sea vehicle components, and onboard piping systems.

- Offshore Platforms: Critical for seawater heat exchangers, firewater systems, and structural components exposed to the splash zone.

From the skin of a supersonic jet to the shell of a chemical reactor, titanium sheets and plates are fundamental materials that enable engineers to build stronger, lighter, and more durable products.

Quick Contact

Related Products

-

Titanium Sheet vs. Plate: A Technical Guide to Selection

Titanium sheets and plates

-

Fabricating with Titanium Sheets and Plates: Cutting, Forming, and Welding

Titanium sheets and plates

Product Categories

- Titanium Anode Basket 1

- Titanium Foils 1

- Titanium Pipes 1

- Titanium Rods 1

- Titanium Tubes 1

- Titanium Wires 3

- Nuts & Bolts 1

- Special Titanium Alloys 1

- Titanium Anodes & Electrodes 1

- Titanium Equipment 1

- Titanium Mesh 1

- Titanium Sheets & Plates 1

- Titanium rods 3

- Titanium foils 3

- Titanium sheets and plates 3

- Titanium pipes 3