Titanium Sheet vs. Plate: A Technical Guide to Selection

While often grouped together, “titanium sheet” and “titanium plate” have distinct characteristics that make them suitable for different applications. Understanding these differences, along with common grades and finishes, is key to selecting the right material for your project.

Sheet vs. Plate: The Thickness Divide

The primary distinction is thickness. While standards can vary slightly, a common industry rule of thumb is:

- Titanium Sheet: Any flat-rolled product with a thickness less than 6.35 mm (0.25 inches).

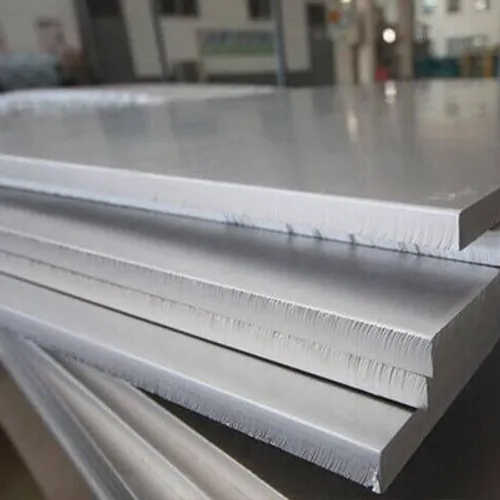

- Titanium Plate: Any flat-rolled product with a thickness of 6.35 mm (0.25 inches) or greater.

This difference in thickness dictates their use:

- Sheets are valued for their formability and are used to create lighter structures, skins, and complex formed parts.

- Plates are valued for their sheer strength and rigidity, used for heavy-duty structural members, pressure vessel shells, and armor.

Popular Grades for Sheets and Plates

- Grade 2 (Commercially Pure): The industry workhorse. It offers excellent corrosion resistance and good formability, making it a top choice for industrial and marine applications (tanks, vessels, heat exchangers).

- Grade 5 (Ti-6Al-4V): The aerospace champion. This alloy is significantly stronger than Grade 2 and is used when high strength is the primary requirement, such as in airframe structures and armor plates. It is less formable than Grade 2.

- Grade 7 (Palladium Alloy): Similar to Grade 2 but with enhanced corrosion resistance due to the addition of palladium. It’s specified for extremely corrosive environments, like in specific chemical processing streams.

Understanding Surface Finishes

The surface finish of a titanium sheet or plate affects both its appearance and subsequent processing.

- No. 1 Finish (HRAP): Hot-Rolled, Annealed, and Pickled. This is a standard finish for titanium plates. It has a rough, matte, non-uniform appearance.

- 2B Finish: Cold-Rolled, Annealed, Pickled, and given a final light “skin pass.” This is the most common finish for titanium sheets, resulting in a smooth, reflective, and uniform surface.

- Polished/Brushed Finish: A secondary process applied for aesthetic purposes, common in architectural and consumer product applications.

Making the Right Choice: When selecting a titanium sheet or plate, consider the required strength, the amount of forming needed, the corrosive environment, and the final aesthetic. This will guide your choice of thickness, grade, and finish.

Quick Contact

Related Products

-

Fabricating with Titanium Sheets and Plates: Cutting, Forming, and Welding

Titanium sheets and plates

-

The Building Blocks of Engineering: Key Applications for Titanium Sheets and Plates

Titanium sheets and plates

Product Categories

- Titanium Anode Basket 1

- Titanium Foils 1

- Titanium Pipes 1

- Titanium Rods 1

- Titanium Tubes 1

- Titanium Wires 3

- Nuts & Bolts 1

- Special Titanium Alloys 1

- Titanium Anodes & Electrodes 1

- Titanium Equipment 1

- Titanium Mesh 1

- Titanium Sheets & Plates 1

- Titanium rods 3

- Titanium foils 3

- Titanium sheets and plates 3

- Titanium pipes 3